Liquid level control is a crucial aspect of various industries, including water management, chemical processing, oil and gas, and many others. Accurate and reliable liquid level monitoring is necessary to ensure optimal operation, prevent spills, and protect equipment from damage. One indispensable device used for liquid level sensing is the float switch.

In this article, we will explore what float switches are, how they work, their applications, and their significance in liquid level control systems.

What Are Float Switches?

A float switch is a simple yet highly effective mechanical device used to detect liquid levels in tanks, reservoirs, or other containers. It consists of a buoyant float, usually made of plastic or stainless steel, attached to a pivoting arm. The float is designed to rise and fall with the liquid level in the container, while the pivoting arm translates this motion into an electrical signal.

How Do Float Switches Work?

Float switches operate on a straightforward principle: the buoyancy of the float changes with the liquid level. When the liquid level is below a certain point, the float rests on the liquid's surface, pulling the pivoting arm down. As the liquid level rises, the float also rises, causing the arm to pivot upwards. This mechanical movement is harnessed to trigger a switch, which can be either a reed switch, magnetic switch, or microswitch.

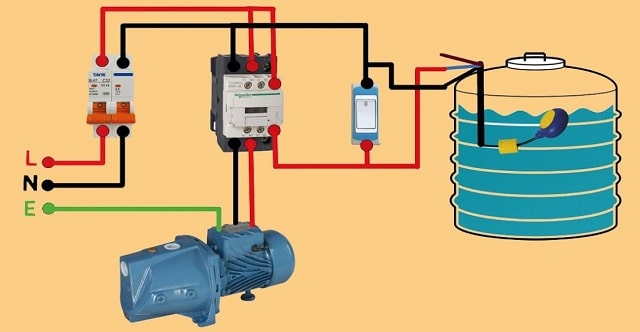

When the float reaches a predetermined level, the switch is activated, and an electrical signal is sent to the control system. Depending on the application, the switch may either open or close the circuit. For instance, in a pump control system, the float switch might turn the pump on when the liquid level is low and off when it reaches a certain high level.

Types Of Float Switches

Vertical Float Switch: The most common type, where the float moves up and down along a vertical stem. They are suitable for use in most tanks and sumps.

Horizontal Float Switch: The float moves horizontally along a guide. They are often used in narrow or constrained spaces.

Cable Float Switch: Instead of a rigid stem, a flexible cable is used with a float at one end and a counterweight at the other. These are ideal for irregularly shaped or small containers.

Electronic Float Switch: Utilizes sensors and electronic components to detect the liquid level, providing more advanced and precise control options.

Applications Of Float Switches

Float switches find applications in a wide range of industries and scenarios, including:

Pump Control: Ensuring the pump starts or stops based on liquid levels to prevent dry running or overflow.

Water Tanks: Monitoring and controlling water levels in residential, commercial, or agricultural water storage tanks.

Sump Pumps: Activating sump pumps to remove excess water from basements or low-lying areas.

Oil And Gas Industry: Detecting oil levels in tanks and preventing overfilling.

Wastewater Treatment: Regulating liquid levels in sewage treatment systems.

HVAC Systems: Maintaining water levels in heating and cooling systems.

Automotive Industry: Monitoring coolant levels in vehicle radiators.

The Significance Of Float Switches

Float switches play a vital role in liquid level control systems, offering several advantages:

Reliability: Float switches are simple and rugged devices, leading to dependable operation and long service life.

Cost-Effectiveness: Compared to other level sensing technologies, float switches are relatively inexpensive.

Easy Installation: They are straightforward to install and require minimal maintenance.

Compatibility: Float switches can work with a wide range of liquids, including water, oil, chemicals, and more.

Safety: By preventing overflow and dry running, float switches help avoid potential hazards and equipment damage.

In Conclusion

Float switches are an integral part of liquid level control systems across various industries. Their simplicity, reliability, and cost-effectiveness make them a popular choice for applications where precise liquid level monitoring and control are essential in multiple industries.

Whether in water tanks, industrial processes, or oil storage facilities, float switches ensure efficient and safe liquid level management, contributing to the smooth functioning of critical operations.