In every brewing process, the end goal is always to achieve the best beer quality. The procedures can be complex and may involve lots of different components. And to get the best results, breweries use different valves that help control fluid flow at various brewing stages. If you run a brewery or are looking to venture into the business, understanding the different types of valves, their applications, and their design specifications is essential. In the sections below, we have discussed all you should know about the different valves used in breweries.

What Is A Valve?

A valve is a component that controls or regulates liquid and gas flow. Valves typically allow full or partial fluid flow and can also be used to restrict the flow path fully. Depending on the size of your brewery and your unique needs or preferences, you can choose either a manually-operated or automated valve. Valves used in breweries usually vary in their capacity to handle various medium flow characteristics such as temperature, pressure and viscosity. Therefore, you must always choose a valve that meets your system requirements.

Valves Used In Breweries

Different kinds of liquids and gases are usually pumped in and out of the brewing equipment during the brewing process. That means different valves will be employed in the process, whether as a direct contact or service utility valve. Keep reading to discover what 6 main valves are used in the specific brewing cycles, their applications, and their pros and cons.

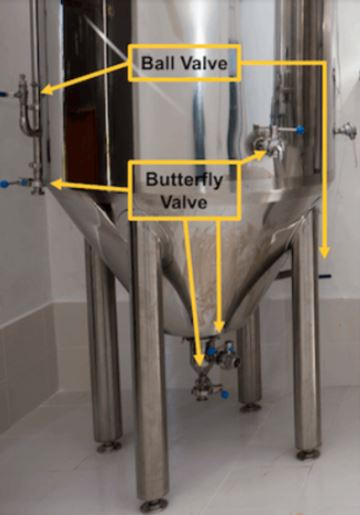

1. Butterfly Valve

Due to their hygienic design, this is one of the most common valves that come into direct contact with various products during the brewing cycle. The valve has a handle that rotates an internal stem which then rotates a disc from a closed to an open state. Butterfly valves have good sealing properties and can be cleaned easily, making them ideal for direct-contact applications. These valves are, however, not ideal for use in high-pressure environments due to the obstructed flow resulting from the stem. They are usually used in tank blow-offs, bottom blowouts, and racking arms.

2. Normally-Closed Solenoid Valve

This valve can be used as a direct contact or service utility valve. The solenoid has an inductive coil that creates an electromagnetic field when energized. This electromagnetic field is the force responsible for the plunger movement. When the power supply is turned on, a magnetic field is created. The field forces the plunger to move upwards, opening the orifice for a smooth and unobstructed flow. Once the power supply goes off, the field disappears, causing the spring action to pull back the plunger. This closes the orifice and hence restricts fluid flow.

The valve has a quick time response making it ideal for automated bottling processes. Since it is normally closed, it is often used as a service utility valve in gas lines for safety reasons. The valve is, however, not ideal for highly viscous or contaminated mediums.

3. Ball Valve

The valve is commonly used as a service utility valve though in rare cases, it can be used as a direct contact valve. A ball valve has a rotary ball that rotates when the valve handle is rotated. The rotary ball usually has a bore that allows or restricts fluid flow. Ball valves are commonly used thanks to their unique design, which allows for unobstructed flow, meaning there is a low-pressure drop. Other benefits include durability and good sealing properties. The only con associated with the valve design is its floating ball which requires frequent cleaning to prevent contamination.

4. Gate Valve

This valve is often used as a service utility valve. It works by screwing a knob that moves the gate/wedge upwards to allow flow or downwards to cut off the flow. The valve usually allows for unobstructed flow and is easy to operate; hence commonly used in water inlets and outlets. Gate valves are, however, not meant for high-pressure applications and circumstances where precise control is needed.

5. Needle Valve

The needle valve is entirely used as a service utility valve due to its internal threads that can easily house bacteria. When the valves handle is screwed, the needlepoint plunger moves upwards or downwards to control fluid flow. The valve’s ability to precisely control flow gives them an added advantage in water or gas lines where hot and cold lines mix to attain a certain temperature.

6. Diaphragm Valve

The diaphragm valve has a knob which, when screwed, moves the steam and the diaphragm downwards, sealing it against the wall of the valve. The valve offers good flow control and is hygienic; hence can be used as a direct contact valve. It is, however, not ideal for high-pressure applications due to the pressure drop associated with the valve design before the bottling or canning process can begin.

Choosing An Ideal Valve For Your Brewery

The brewing industry is regulated with standards and safety policies that every brewery must adhere to. When choosing a valve for your brewery, you want to pick certified materials that are not only rated for your industry but also durable and efficient. Ideally, you should choose stainless steel and valve seal made from EPFM or PTFE (Teflon). The valve connection and ease of cleaning are the other factors to consider. Where necessary, consult a professional to avoid costly mistakes during the selection process.